Offset Printing

In Coral Print N Pac, we are dedicated to use the latest litho printing technology and equipment for our paper packaging products.

Litho Offset Printing delivers the exceptional high graphics with vivid colors and sharp images. Unlike the flexographic printing, an inked image is transferred from the printing plate to a rubber blanket cylinder first, then to the paper. This is a lithographic process based on the repulsion of oil and water. It is very suitable for the medium to long printing run. Our litho printed products include:

- Custom Paper Printed Boxes

- Cosmetic Packaging Boxes

- Luxury Paper Shopping Bags

- Corrugated Cartons / Boxes etc

Screen Printing

Screen printing is more versatile than traditional printing techniques. The surface does not have to be printed under pressure, unlike etching or lithography, and it does not have to be planar. It can be used to print on a wide variety of substrates, including paper, paperboard, vinyl and many other materials. Some common products from the screen printing industry include custom paper boxes, posters, labels, decals, signage etc.

Gloss/Matt Lamination

Coral Print N Pac provides the various laminating options for custom paper boxes and bags, including the glossy and matt lamination. The custom paper box is laminated to protect it from stains and moisture, to increase its strength and durability, and to add sheen and vibrancy to its ink.

Gloss Lamination

The glossy laminating provides a more brilliant glossy sheen to the custom paper box than the UV glossy coating or varnishing. It is a great a way to give a clean modern look to the custom paper box.

Matt Lamination

While the matt laminating can be an effective way to give the custom paper box a nice smooth look and a luxury quality feel. It works great with designs and color pallets that are subdued.

Gloss/Matt Varnish

In Coral Print N Pac, the glossy varnishing, matt varnishing are available to our custom paper boxes, printed paper boxes, cosmetic paper boxes, custom paper bags, corrugated printed boxes and rigid paper boxes, cardboard gift boxes.

Gloss Varnish

With the glossy varnish, the printed box surface is smooth, shiny and glossy. In the sunshine, the surface reflects light quite efficiently. Therefore, a glossy varnished printed box usually has the very bright and lustrous color.

Matt Varnish

A matt varnish gives the printed box a non-glossy, smooth even surface free from shine. This matt finish on the printed box adds to the feeling of luxury. It is the most popular finish used in the luxury packaging of the cosmetics and jewelry products and etc when the seller wants to impart a luxury quality feel to the potential customers.

Spot UV

With the spot UV, the UV inks are only applied to the specific area of the printing surface to highlight specific texts or images, particularly the logo. The Spot UV on the brand logo is widely used for the luxury paper bags, boxes, gift boxes, cosmetic packaging boxes, jewelry boxes, and some retail packaging boxes.

Hot Foil Stamping

Hot foil stamping is a special finish where the foil film is used to create striking designs and graphics on the custom paper printed box. It gives the paper printed box a shiny and incredible look, adding a very luxury feel. The foil can be almost any color. The foil films come in rolls in a wide assortment of colors, finishes, and optical effects. Hot Foil stamping finish is available in Coral Print N Pac for the custom paper boxes, corrugated printed boxes, cosmetic paper boxes, rigid paper boxes and custom paper bags.

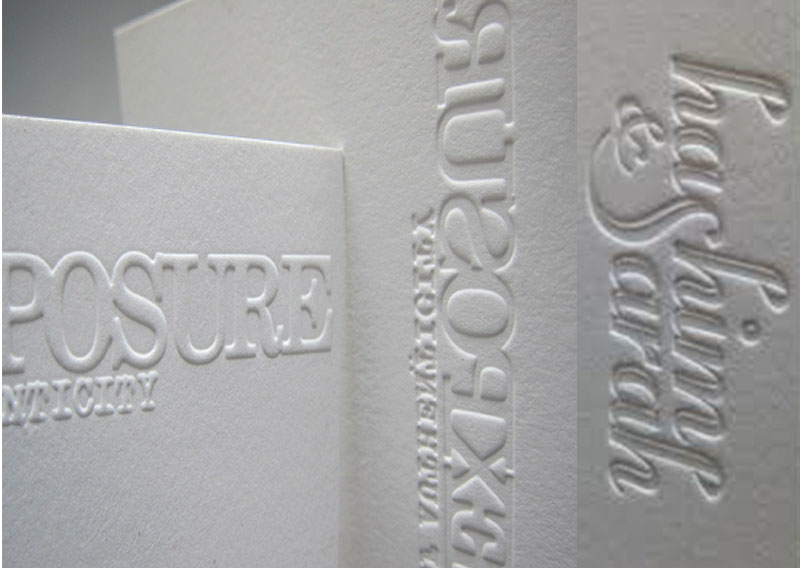

Embossing and Debossing

Debossing and embossing are used to imprint images onto paper, leather, or vinyl and are widely used on the luxury packaging, like the cosmetic paper boxes, luxury paper bags and rigid boxes. In embossing, an image is pressed into the material so that the image rises from the surface. Debossing is the opposite of embossing; the area around the image is pressed so that the image is pushed down into the material rather than raised.

Die-cutting

For the custom paper boxes, die-cutting is a manufacturing process, using die to cut various custom shapes out of the paperboard and to crease various custom folding lines on the paperboard. The die-cutting is an indispensable procedure during the production of the paper printed boxes, corrugated printed boxes, rigid paper boxes and custom paper bags.

Aqueous Coating

Coral Print N Pac supplies the custom paper printed box, corrugated printed box and custom paper bag with the aqueous coating. Aqueous Coating also referred to as the AQ coating, is a water based coating applied on the print surface. Like the varnish coating, it protects the print surface from rough-handling, scuffing during the transits and distribution. The AQ coating is usually applied on all-over the printing surface of the box, which offers a better protection than the Gloss Varnish Coating.